Collision Pros Magazine 2018 | ISSUE 3

Zero Point Calibration

WHY AND WHEN IT NEEDS TO BE PERFORMED

Here’s one way to think about the alignment of the Millimeter Wave Radar Sensor: Imagine a boy walking home from school. There’s a large wooden fence, and the boy wants to see what’s on the other side. He looks for a knothole and then lines it up with his eye. If his eye is not lined up, then he’s not going to see what he wants to see. The same principle applies to a Millimeter Wave Radar Sensor if it’s not properly aligned to “see” what’s in front of the vehicle, then the safety systems cannot perform as designed. The key is to properly align the sensor so it’s not focused on the ground, or pointing to the sky, but is looking ahead as intended.

TODAY’S TOYOTA AND LEXUS VEHICLES FEATURE A VARIETY OF DRIVER ASSIST SAFETY SYSTEMS.

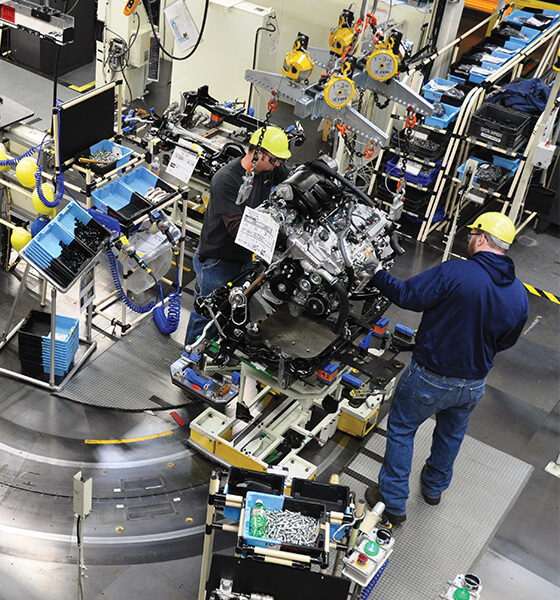

These safety systems require system checks and alignment when a sensor is involved in a collision. To be specific, Zero Point Calibration is a necessary procedure when a repair involves wheel alignment, or when components that the front Millimeter Wave Radar sensor are attached to need to be changed. This is to make sure the Millimeter Wave Radar Sensor is aligned correctly to the vehicle and to the direction of travel.

Early on, vehicle safety technology may have required some simple steering angle sensor calibrations, but with the evolution of modern safety systems, more involved calibrations have become necessary to be sure all of the safety systems are working properly and as designed. The days of “set the toe and let it go” are long gone, and ignoring details like required calibrations after wheel alignment have the potential for causing safety system malfunctions because of out-of-spec parameters.

Some examples of when a Millimeter Wave Radar Sensor should be aligned and calibrated are: Whenever an equipped vehicle has a wheel alignment, has had a sensor removed and reinstalled or replaced, and, when any part that the sensor is attached to has been removed and reinstalled or replaced. From a collision repair point of view, that means any time a vehicle has had a bumper cover or grille removed and reinstalled or replaced, or needs a wheel alignment. Whether it’s part of a collision repair or for normal maintenance, the repair manual should be reviewed to confirm if a related system needs adjustment or calibration.

ALIGNMENT AND CALIBRATION

The proper procedures for zero-point calibration after wheel alignment, sensor alignment and calibration procedures can be found in vehicle-specific repair manuals on the Technical Information System (TIS). Sensor alignment and calibration requirements will be listed in multiple locations, and zero-point calibration procedures can be found in the Wheel Alignment Procedures section. A Techstream and Reflector Special Service Tools (SSTs) are required to clear data and perform calibrations.

Depending on the level of technology available in a vehicle, calibration procedures may vary. For example, after wheel alignment:

- A 2018 RAV4 requires Yaw Rate Sensor Zero Point Calibration to complete the procedure.

- The 2019 Avalon gas models require a System Variant Learning and Acceleration Sensor Zero Point Calibration, while the Hybrid Avalon requires you to clear the Zero Point Calibration Data and perform Yaw Rate and Acceleration Sensor Zero Point Calibration.

Once a Millimeter Wave Radar Sensor is properly aligned and calibrated, a health check scan should be performed to make sure all electronic systems are diagnosed as operationally correct and no Diagnostic Trouble Codes (DTCs) are present. Performing Zero Point Calibration will ensure that the vehicle has been properly repaired and is working as designed. In addition, keep in mind that Zero Point Calibration during the repair process should factor into your estimate.