Collision Pros Magazine 2021 | ISSUE 1

HOW TO NAVIGATE TIS

FIX IT RIGHT THE FIRST TIME

Technical Information System (TIS) is Toyota’s service and collision support source for access to the latest Toyota product and repair information. This web-based database includes service bulletins, tech tips, repair manuals, collision repair manuals, electrical wiring diagrams, new car features, mechanical and collision procedures and factory training information. In this article, we’ll show you how to find what you need quickly and efficiently.

TIS BASICS — BE A DETECTIVE

First and foremost, you need a TIS subscription and an account. Once you have your account, sign in and then search for the vehicle that is in your shop. For this story, we’ll focus on the 2021 Sienna HV.

HOW TO LOG INTO TIS

TIS is an invaluable tool that’s there to help you repair Toyota and Lexus vehicles when they come into your facility.

To create an account, click Subscribe and choose the option that’s best for you.

To access TIS, go to techinfo.toyota.com.

Three of the most used manuals in TIS are the New Car Features (NCF), the Repair Manual (RM) and the Collision Repair Manual (CR). To access the appropriate manual, log into TIS, enter the model and year and click on NCF, RM or CR.

Before you start repairs, a good place to search is the Introduction Section for that vehicle. There you can see what documents exist, such as precautions for working on the airbag system or the blind spot monitor, welding information or anything else that is appropriate for that vehicle.

Another helpful document is the Damage Diagnosis document. Here’s how to find it:

- Go to the appropriate model and year.

- Find the Collision Repair Manual tab.

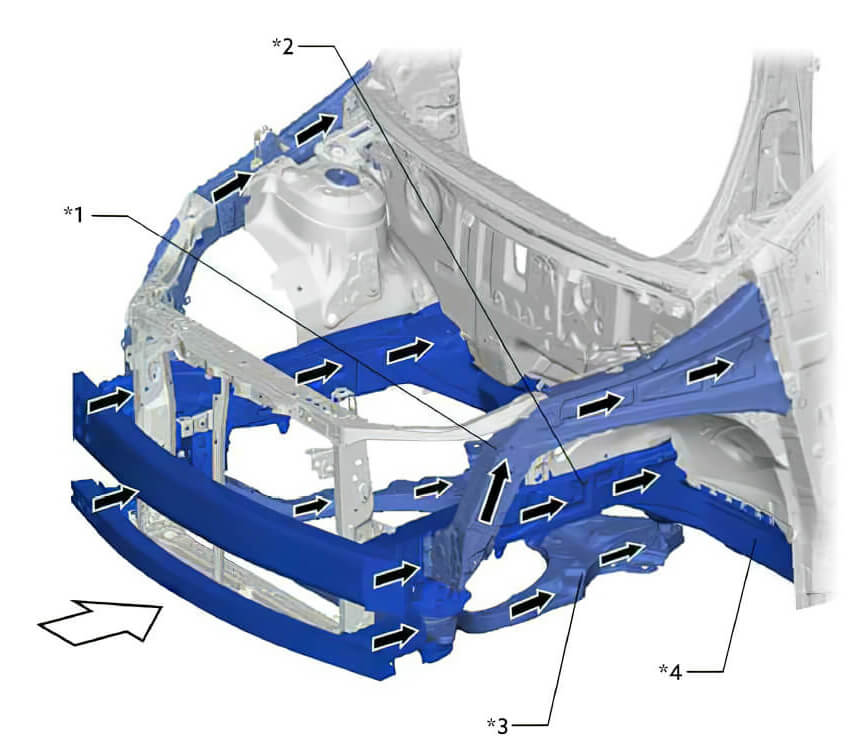

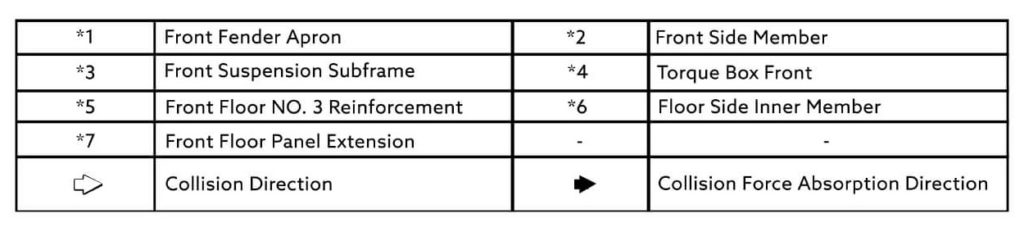

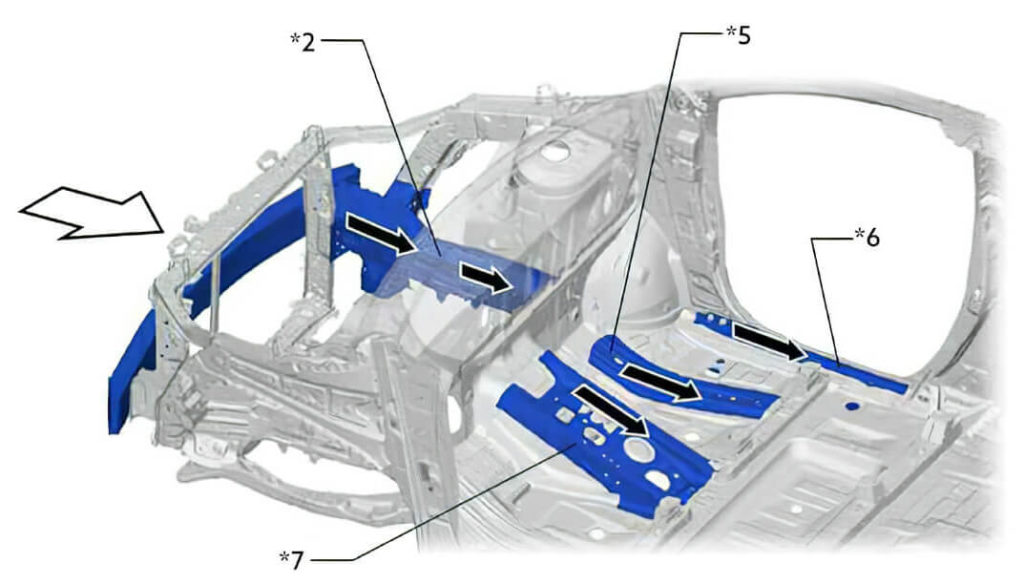

- Select Damage Diagnosis document, which shows how the forces of a collision are transferred throughout the vehicle, helping you know where to look for potential damage:

The Damage Diagnosis document also details a variety of collision scenarios—for example, a head-on collision, rear-end collision or side impact. Each diagram outlines how collision forces (white arrows) are diverted in an accident (black arrows). For example, in a front impact you can see how the forces are diverted along the front fender apron, front side members, front suspension subframe and all the way to the floor side inner members. The floor side inner members can be easily overlooked during an inspection, but they may also need repair. Seeing where crush zones are located and how they’re designed to give makes it easier to determine which components need to be replaced or repaired.

As a rule of thumb, whenever a location is damaged or if you have to replace parts, you should always check the Repair Manual for the appropriate removal, inspection and installation procedures.

IT’S ALL ABOUT EVOLUTION

Another benefit of using TIS is that it is constantly expanding and evolving. As new information is discovered, it’s entered on TIS. That way, you might discover that a new process supersedes a process you had used in the past.

One more recommendation for each vehicle you’re working on: Take notes on the repairs. Document things you learned or that challenged you during the repair. That way, you can refer back to your notes when you encounter a similar issue. And always check TIS when you start working on a new project, as information is constantly being updated and there may be new procedures.