Collision Pros Magazine 2020 | ISSUE 01

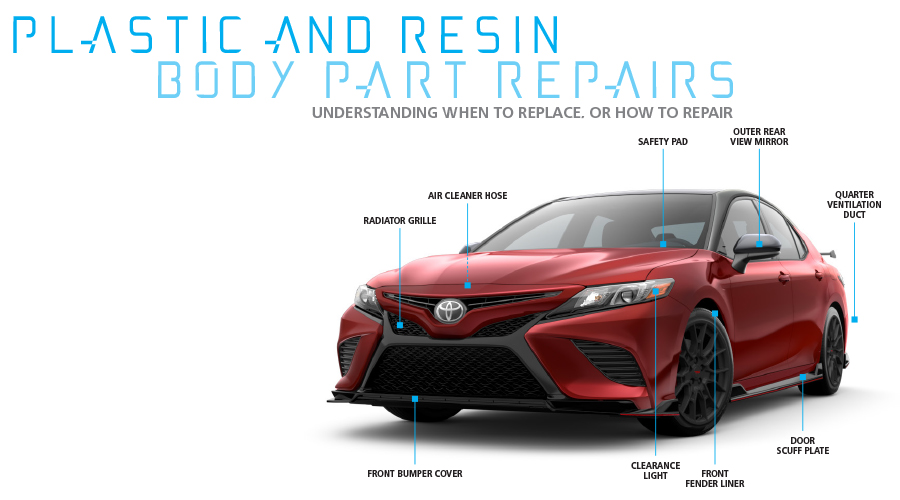

PLASTIC AND RESIN BODY PART REPAIRS

Understanding When to Replace, or How to Repair

WEIGHT AFFECTS EFFICIENCY. That’s why Toyota and Lexus use various plastic and resin body parts, which are lighter than steel. Some vehicles used to be manufactured with aluminum hoods and trunks to reduce weight. However, aluminum is expensive and hard to repair. Now, on select Toyota and Lexus vehicles, aluminum has been replaced with resin.

When a Toyota or Lexus is in your shop and has plastic or resin body parts, you’ll need to question if the part should be replaced or repaired. If a repair is the answer, you’ll need to know the proper repair techniques.

THE BASICS

Plastics fall into two basic categories of synthetic resins: thermoplastic and thermoset. The question of whether a part can be repaired or replaced requires knowledge of the damaged parts and answers to these three questions:

- Does the repaired component meet factory appearance and fit?

- Does it meet factory function standards?

- Does it pass factory safety standards?

If the answer is “no” to any of these questions, then the component should be replaced with a Toyota Genuine part and not repaired. If you’re unsure, then the best way to proceed is to replace the part.

The difference between thermoplastic and thermoset:

- Thermoplastic resins begin as liquid and can be either soft or hard. They can be softened repeatedly by heating or adding solvents, and become solid after cooling or after the solvent has evaporated. An example of a rigid thermoplastic component is a side mirror housing or door handle. An example of a flexible thermoplastic component is a front or rear bumper facia or fender wheel liner.

- Thermoset resins also begin as a liquid, but change into a solid when chemical hardeners or a catalyst are added. They cannot be softened like thermoplastic parts, and are generally hard and can be brittle. Most thermoset parts are resistant to most solvents. Thermoset components include carbon fiber reinforced plastic, sheet molded compounds, polyurethane, polyester and epoxy resins, all of which are inflexible. Examples of rigid thermoset plastic components include truck bed liners, some spoilers, and the 2012-2018 Prius v polycarbonate roof.

HOW DO YOU KNOW WHICH IS WHICH?

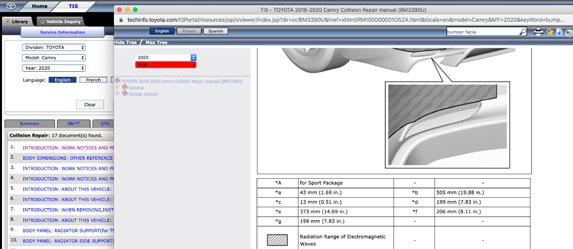

For collision repair, you need to know which material you’re working with—thermoplastic or thermoset—and if it’s repairable or if it must be replaced. You can start by referring to Toyota’s Technical Information System (TIS) https://one.tis.toyota.com. Look up the specific make, model, and year of the vehicle and go to the Collision Repair tab. This will show you the attachment location and identifies the type of plastic used in that part.

HANDLING RAW PLASTIC BUMPERS

When a damaged plastic bumper needs to be replaced, proper preparation and refinishing are required to ensure high quality, long-term durability and customer satisfaction. You’ll find Toyota’s recommended procedures for cleaning and preparing original equipment raw plastic bumpers in Collision Repair Information Bulletin (CRIB) 170.

KNOW YOUR PLASTICS BEFORE STARTING A REPAIR

Be sure to follow the recommended procedures based on the parts you’re working with to ensure you return a vehicle that looks perfect, functions as new, and maintains Toyota and Lexus safety standards.

HERE ARE A FEW EXAMPLES OF WHAT YOU’LL FIND IN TIS:

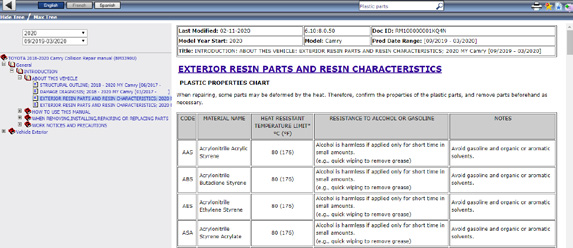

Once you’ve identified the model and year, you can search for parts characteristics and precautions. Here, for example, you’ll find exterior resin parts and resin characteristics for a 2020 Camry.

Here, under the “Work Notices and Precautions” section, you find the areas on a 2020 Camry bumper facia that can be repaired, the repair limitations, and refinishing specifications.

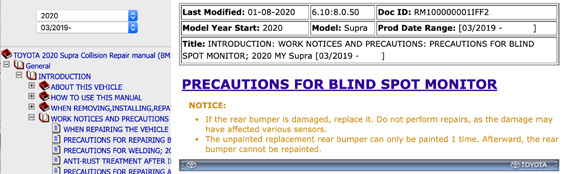

In this example from the TIS Body Repair Manual you see the 2020 Toyota Supra rear bumper facia. Note that under the “Work Notices and Precautions” section no repairs are to be performed—the part must be replaced if it is damaged.