EXPLORING TOYOTA’S VEHICLE METALS

Collision Repairability Guidelines

Toyota uses mixed materials when manufacturing its vehicles. When a Toyota vehicle needs collision repair, Toyota recommends that auto body technicians review and understand the vehicle’s repairability guidelines before beginning the repair process.

BECOME A DETECTIVE

Toyota provides the resources you need. For instance, if the new 2022 Toyota Corolla Cross gets in an accident, it’s critical to know what’s under that paint.

First, you’ll need to review the vehicle repair manual and investigate the types of metals used to manufacture the vehicle, as well as the recommended procedures for repair if appropriate. If you do this, then you are on your way to fixing it right the first time!

TYPES OF METAL USED IN AUTOMOTIVE MANUFACTURING

By weight, numerous metals comprise most of the vehicle. Let’s look at a few of the metals used in the manufacturing of Toyota vehicles.

Steel — is strong and the primary metal used to manufacture most vehicles and is a refined version of iron and can include:

- Mild steel

- High-strength steel

- Ultra-high-strength steel

- Stainless steel*

- Galvanized steel*

*Typically, you will not have to deal with stainless steel or galvanized steel when making structural collision repairs.

Steering and suspension are, for the most part, made from steel along with parts of the body, wheels, chassis, and frame. Steel is durable and flexible.

Aluminum — is a fast-growing rival of steel and is now used more often in modern vehicles because it’s light and reduces the vehicle’s weight. Aluminum is lighter than steel and by weight stronger as well. Parts of a vehicle that are typically made from aluminum include various engine components and wheels, but can also be found in some vehicle hoods such as the 2017-2022 Prius Prime hood.

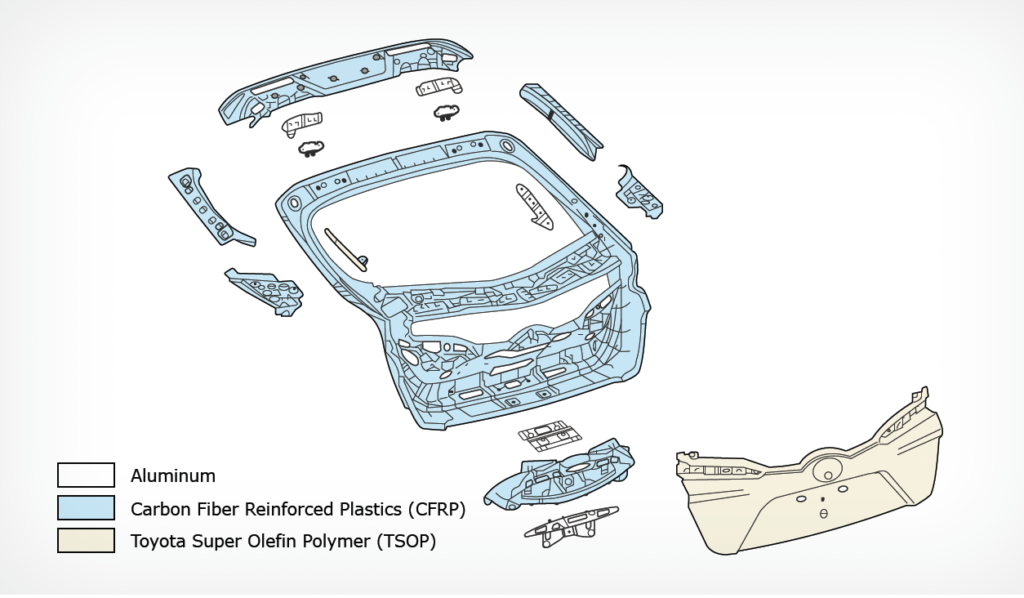

Carbon Fiber — was typically reserved for sports cars because it reduces the weight of the vehicle. However, today Toyota uses carbon fiber in many of its vehicles, especially in vehicle hoods. Additionally, Toyota used carbon fiber to help make their Prius Prime more spacious by using the material for its liftgate. When repairing carbon fiber, be sure to review repairability and guidelines.

For example the 2017 – 2022 MY Prius Prime

Carbon Fiber can be found in the reinforced plastics liftgate.

EXTERIOR PANELS: Aluminum, Carbon Fiber Reinforced Plastics (CFRP), and Toyota Super Olefin Polymer (TSOP)

In some instances, Toyota uses carbon fiber reinforced plastics (CFRP) on pieces like the liftgate to reduce weight without compromising rigidity.

Iron — is also strong, but it’s no longer used in areas such as body panels because of its weight. Iron is still used for components like engine blocks, camshafts, brake rotors, and steering components.

Metals Rarely Used Today:

Magnesium — known for its lightweight and high cost

Titanium — also known for its lightweight and high cost

Today’s Vehicles

Various grades of steel are being used more and more in vehicles like the Corolla Cross because they reduce the overall weight without compromising the strength of the body. This helps modern vehicles be lighter and, as a result, more fuel-efficient.

As reported by the World Steel Association*, a 2019 study by the International Organization of Automobile Manufacturers stated that, on average, each vehicle manufactured is made up of an average of 1,984 lbs. of steel:

- 40% is used in the body structure, panels, doors, and trunk closures for high strength and energy absorption

- 23% is in the drivetrain, including cast iron for the engine block

- 12% is in the suspension components

- The rest is in the wheels, fuel tank, steering, and braking systems

Because today’s vehicles are comprised of mild steel, high-strength steel, ultra-high-strength steel, aluminum and, in some cases, carbon fiber, the first step at your collision repair facility is to refer to the Toyota Information System (TIS). Make sure you understand how to properly repair the damage and recognize that each vehicle may differ, not only by model but by trim level and the dealer-installed accessories that may have been added to the vehicle.

FINDING OUT WHAT TYPE OF METAL IS USED IN A TOYOTA

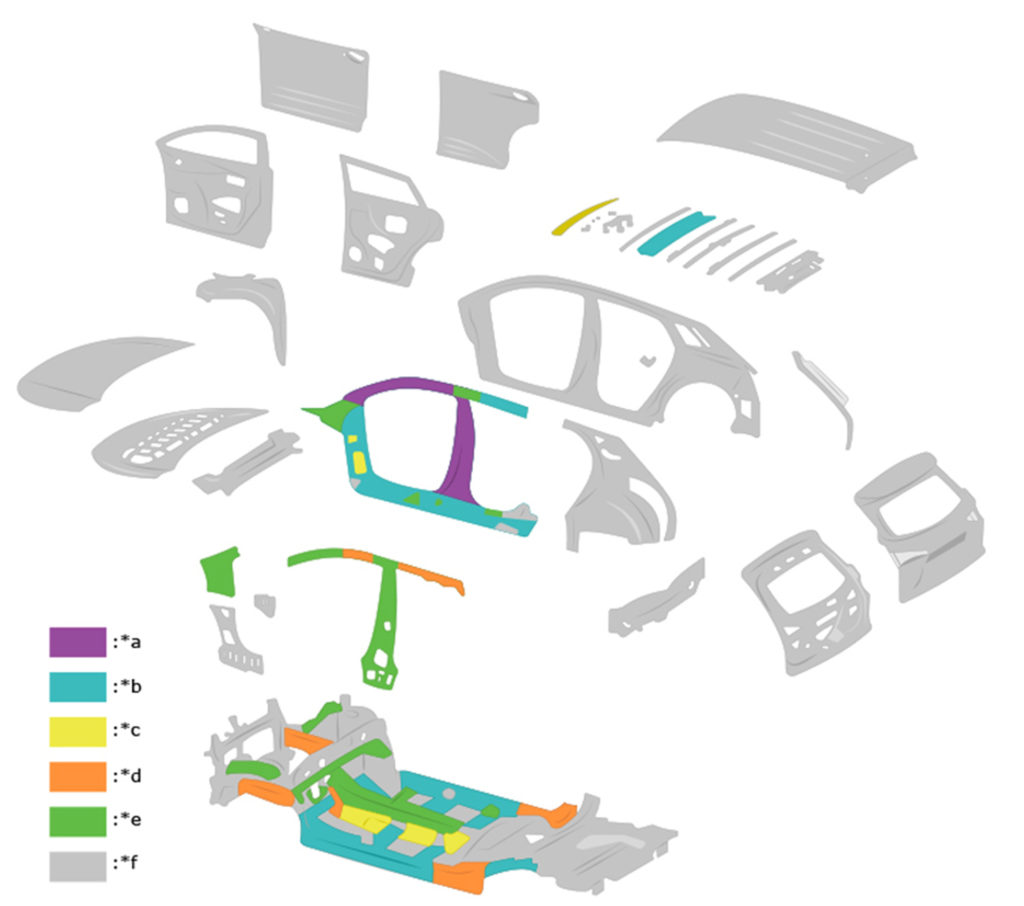

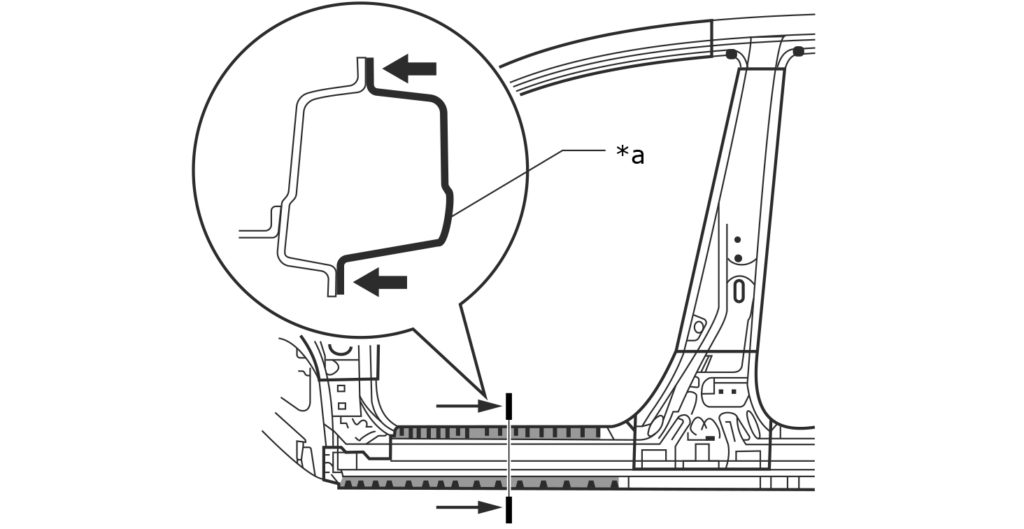

The accompanying illustration shows the different types of metal used in the 2022 Corolla Cross**. As you can see, if the vehicle was hit on the driver’s side, you will need to refer to TIS to discover the different types of metal you will be working with during the repair.

*a Hot-stamped Steel (Tensile Strength: 1500 MPa Class)

*b Ultra High-tensile Strength Steel

(Tensile Strength: 1180 MPa Class)

*c High-tensile Strength Steel (Tensile Strength: 980 MPa Class)

*d High -tensile Strength Steel Sheet (780 MPa)

*e High -tensile Strength Steel Sheet (590 MPa)

* f High-tensile Strength Steel (Tensile Strength: Under 440 MPa Class)

So, when a vehicle arrives at your facility, you need to investigate which types of steel you are going to be working with. Here is how to check:

- Go to the Toyota TIS website and log in

- Enter:

- Division: Toyota

- Model: for this example, we will use Corolla Cross

- Year: for this example, we will use 2022

- Service Category: for this example, select Vehicle Exterior

- Section: leave as “ALL” or select from: Body Structure, Door/Hatch, Exterior Panels/Trim, Frame/Unibody, Paint/Coatings —or whatever area is damaged on the vehicle that is in your shop

- Keyword: Enter

- Hit “Search”

- Select the “CR” tab — for Collision Repairs — there, you can see all of the applicable topics

Note: If you leave “Service Category” as “ALL,” you will get more results, particularly under the “NCF” tab, which stands for New Car Features. This is where you can find information not only about the body structure but about the various sensors that are on a particular vehicle.

Under the “CR” tab, you will find valuable information such as:

- Illustration of Weld Points

- Work Notices and Precautions when Repairing the Vehicle Body and Precautions for Repairing Body Structure (including Crush Boxes)

- Damage Diagnosis

You should also check under the “ACCY” Accessory tab to see if there are any applicable documents that could affect your repairs.

PRECAUTIONS FOR WELDING

*a 1500 MPa or 1180 MPa or 980 MPa or 780 MPa ultra high strength steel

When you have to weld, be aware that the welding instructions vary based on the metal you have to weld***.

- You need to follow the appropriate instructions to ensure the repair has sufficient weld strength. See Notice ***

FOOTNOTES:

*As reported by WorldSteel.org https://www.worldsteel.org/steel-by-topic/steel-markets/automotive.html

**TIS Doc ID: NM100000001YR61

***TIS Doc ID: RM100000001ZKT9